CORROSION CHART

Marine Environment

When building within one kilometre of the coast, please refer to the Building Code of Australia. The BCA provides ‘standards’ for coatings on external structural steelwork in relation to the distance from salt water and the distance from breaking surf. For instance, coastal envrironments within 100 metres of breaking surf are classified as a severe enviroment and BlueScope Lysaght® recommends the use of COLORBOND® Ultra steel these situations. This affects compliance and warranties.

Material Compatibility

Due to phenomenon known as galvanic or bi-metallic corrosion, some commonly used metals can cause accelerated corrosion when used with ZINCALUME® steel, zinc/aluminum alloy coated and COLORBOND® prepainted steel.

Corosion Chart

The further apart the two metals on this chart, the faster the corrosion will take place.

| +VE Anodic | |

|---|---|

| ZINC |  |

| ZINCALUME | |

| ALUMINIUM | |

| CADMIUM | |

| HIGH STRENGTH ALUMINIUM | |

| SOFT SOLDER | |

| LEAD | |

| TIN | |

| BRASS | |

| COPPER | |

| BRONZE | |

| SILVER | |

| -ve Cathodic |

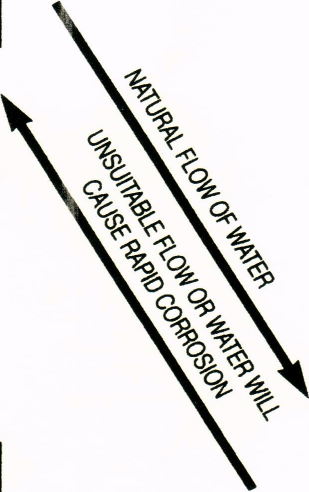

ACCEPTABLE DRAINAGE FROM ONE SURFACE TO ANOTHER

| LOWER SURFACE | UPPER SURFACE | |||||||

|---|---|---|---|---|---|---|---|---|

| GAL | ZINCALUME | COLORBOND | S/STEEL | ALUMINIUM | COPPER | ZINC | LEAD | |

| GAL | YES | NO | NO | NO | NO | NO | YES | Y/NC |

| ZINCALUME | YES | YES | YES | Y/NC | YES | NO | YES | NO |

| COLORBOND | YES | YES | YES | Y/NC | YES | NO | YES | NO |

| S/STEEL | Y/NC | Y/NC | Y/NC | Y/NC | Y/NC | Y/NC | Y/NC | Y/NC |

| ALUMINIUM | YES | YES | YES | Y/NC | YES | NO | YES | Y/NC |

| COPPER | Y/NC | Y/NC | Y/NC | YES | YES | YES | YES | Y/NC |

| ZINC | YES | NO | NO | NO | NO | NO | YES | Y/NC |

| LEAD | Y/NC | Y/NC | Y/NC | Y/NC | Y/NC | Y/NC | Y/NC | YES |

| NOTE : | YES | CONTACT AND DRAINAGE ACCEPTABLE | ||||||

| Y/NC | DRAINAGE ACCEPTABLE BUT NOT DIRECT METAL CONTACT | |||||||

| NO | NO DRAINAGE ACCEPTABLE AND NO DIRECT METAL CONTACT | |||||||